Abstract

The edge-to-edge connected metal-semiconductor junction (MSJ) for two-dimensional (2D) transistors has the potential to reduce the contact length while improving the performance of the devices. However, typical 2D materials are thermally and chemically unstable, which impedes the reproducible achievement of high-quality edge contacts. Here we present a scalable synthetic strategy to fabricate low-resistance edge contacts to atomic transistors using a thermally stable 2D metal, PtTe2. The use of PtTe2 as an epitaxial template enables the lateral growth of monolayer MoS2 to achieve a PtTe2-MoS2 MSJ with the thinnest possible, seamless atomic interface. The synthesized lateral heterojunction enables the reduced dimensions of Schottky barriers and enhanced carrier injection compared to counterparts composed of a vertical 3D metal contact. Furthermore, facile position-selected growth of PtTe2-MoS2 MSJ arrays using conventional lithography can facilitate the design of device layouts with high processability, while providing low contact resistivity and ultrashort transfer length on wafer scales.

Similar content being viewed by others

Introduction

The scaling of the dimensions of electronic components is essential to increase the density of devices in an integrated chip (IC)1,2. To fulfill industrial requirements, the transistors in ICs must have both ultrashort physical lengths of the gate (L < ~12 nm) and contact (Lc, which should be smaller than the required tightest metal pitch, ∼16 nm) by 20341,3. In this respect, two-dimensional (2D) van der Waals (vdW) materials have emerged because of their higher carrier mobility and superior electrostatic controllability at the atomically thin limit1,2 to achieve channel scaling for future nanoelectronics. However, fundamental limitations in producing ultra-scaled, low-resistance contact electrodes for 2D semiconductors (e.g., transition metal dichalcogenides (TMDs))2,4 using a conventional 3D metal contact limit the switching performance of transistor. For example, the deposition of the 3D metal contact onto 2D semiconducting TMDs typically yields a disorder-rich interface at the metal-semiconductor junction (MSJ), resulting in high contact resistance (Rc)2,4. Furthermore, the resultant 3D/2D MSJs have inevitably long transfer length (LT) of charge carriers (e.g., LT > ∼50–200 nm)5,6,7,8,9,10, which leads to an exponential increase in Rc with the reduction in the contact size if Lc is smaller than LT (i.e., Lc < LT), prohibiting prospective contact scaling.

To avoid the problems associated with conventional vertical contact, pioneering works on the use of edge-to-edge connected lateral 3D-2D (or 2D-2D) MSJs have been conducted5,11,12,13,14,15,16,17. It has a directly metalized junction with strong hybridization, and the absence of atomic discontinuities or defects at the lateral MSJs facilitates superior contact between the 2D semiconducting TMDs and metal electrodes (i.e., smaller Rc)5,11,13. Furthermore, using a lateral MSJ has a significant advantage in lowering the LT because the carriers are only injected through the few-atom-thick interface (i.e., LT decreases to a few nm). Thus, the lateral MSJ-based transistor performs excellently even if Lc is reduced to the sub-nm range5. However, owing to the general thermal and chemical instability of TMDs, practical techniques for controlling heterogeneous integration are highly challenging. Only proof-of-concept has been demonstrated5,11,13,14,15,16,17, thereby failing to achieve high yield and high device density. For instance, obtaining edge contact by lithographic techniques requires that the 2D semiconductors be protected against oxidizing conditions using a passivation layer (e.g., hexagonal boron nitride)11,13, or in-situ etching prior to edge metallization5.

Chemical vapor deposition (CVD) of TMD-based 2D-2D MSJ heterostructures lacks the control of spatial locations12,14,15, and their active layer is inevitably degraded by thermal budget effect because the synthesis of 2D semiconductors along the edge of 2D vdW metals are still at the embryonic stage of development. Although graphene has been widely studied for low-resistance contacts with 2D semiconductors16,17, the large lattice mismatch between graphene and the 2D semiconductor, along with the polymer-based residues incorporated into the assemblies during the graphene-transfer processes, commonly hinder the production of edge-contacted in-plane 2D-2D MSJs and limit the performance of the contacts16,18. Recent studies have demonstrated significant advances towards fabricating lateral 2D-2D MSJs using irregularly-formed flakes of 2D vdW metals, Mo2C and VS214,15. However, for the approach to be practical and scalable, limitations in terms of the reproducibility of conformal MSJ patterns with sub-1-nm LT on a large scale and low Rc through the suggested approach need to be addressed. Therefore, in the long term, it is vital to develop a groundbreaking technique for fabricating a 2D vdW metal with high stability and processability that can offer a substantial degree of freedom in the device architecture.

Here, we demonstrate the formation of synthetic edge contacts consisting of metallic 2D vdW PtTe2 crystals with high thermal stability and the facile position-selected growth of conformal lateral 2D-2D MSJ patterns using conventional lithography. We investigated the high thermal stability of PtTe2 under ultrahigh vacuum (UHV) (which maintained its intrinsic surface property up to ∼825 °C) and succeeded in obtaining edge-directed PtTe2-MoS2 lateral heterojunctions by using two-step CVD. The resultant epitaxially grown lateral MSJ sustained almost ideal stoichiometry without the development of thermally induced voids or the production of mixed alloys. The monolayer MoS2 MSJ transistors with PtTe2 edge contacts exhibited superior n-type carrier transport compared to those with 3D vertical contacts, attributed to both the reduced thermionic emission at the Schottky barrier and the lack of interfacial defects. Additionally, the position-controlled growth of PtTe2 and subsequent chemical assembly to MoS2 allowed us to obtain 2D TMD-based synthetic edge contact arrays on a large scale. The patterned MSJ showed ultralow contact resistivity (> 11.7 Ω·μm2), which is almost one order of magnitude smaller than those of typical 3D top contact electrodes (∼103 to 105 Ω·μm2), along with a significantly short LT (∼0.7 nm), indicating the potential of PtTe2 for affording drastically miniaturized high-quality metal contacts to atomic transistors.

Results

Synthetic strategy for high-quality, edge-contact MSJ

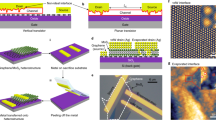

To produce electronic-grade edge contacts, we developed a synthesis method for lateral MSJs that ensures high-quality MoS2 as a channel material. Many previous studies on lateral MSJs prepared using CVD rely on the growth of 2D metals after the preparation of 2D semiconductors because typical 2D semiconductors (e.g., WS2, MoSe2) require a relatively high growth temperature (∼700–800 °C) compared to vdW metals (e.g., ∼600 °C for NbS2 or VSe2)19,20. However, this sequence for two-step CVD can thermal degrade 2D semiconductors, substantially lowering the performance of resultant device because of the increased chalcogen vacancies of the channel21. Instead, we developed a technique to create a 2D semiconductor (i.e., MoS2) after preparing 2D metal (i.e., PtTe2) to produce a high-quality semiconducting 2D sheet in the lateral MSJ (Fig. 1a, b).

a Schematic of the growth process for the PtTe2 flakes at a growth temperature of 700 °C. b Schematic of the growth process of MoS2 along the edge of PtTe2. The insets of (a) and (b) show the representative false-colored scanning electron microscopy (SEM) image of the synthesized PtTe2 flakes and PtTe2-MoS2 heterostructures on SiO2/Si substrate. c Raman spectra of multilayer PtTe2 flakes displaying strong Eg and A1g signals (vertical dashed lines) without any substantial differences up to 900 °C annealing under UHV conditions. d Benchmark plots of metallic TMDs such as 1T’-WTe231,35, 2H-NbSe232,37, 1T’-MoTe233,38, 1T-TaS236,39, and 1T’-MoS234 with respect to the room-temperature electrical resistivity (ρ) and the endurance temperature, T, that the material can tolerate without structural degradation. The endurance T of the metallic TMDs were characterized under vacuum (solid) or Ar atmosphere (binned). e Confocal Raman spectrum captured at the heterojunction’s interface, PtTe2, and MoS2 flakes. The vertical lines indicate Eg and A1g modes from PtTe2, and E2g and A1g modes from MoS2. f Atomic force microscopy (AFM) height profile along the red line displayed in the corresponding AFM image (inset, with a scale bar of 2.5 μm; the MoS2 boundary is indicated as white dashed lines.), indicating the synthesized MoS2 forms a monolayer (H ≈ 0.78 nm) while the PtTe2 forms multiple layers (thickness, H ≈ 28 nm). g, h X-ray photoelectron spectroscopy (XPS) analysis of the PtTe2-MoS2 heterostructure. For comparison, the spectra of bare MoS2 grown independently on the substrate and those of Ti-deposited MoS2 are displayed. The XPS profiles of the for Mo 3d, and S 2p regions are shown in (g) and (h), respectively. The XPS Mo 3d3/2, Mo 3d5/2, S 2p1/2, and S 2p2/3 peaks are specified by dashed lines. i, j Transmission electron microscopy (TEM) investigations of the heterostructure consisting of a multilayer PtTe2 with a monolayer MoS2. i Selected area electron diffraction (SAED) patterns of the MoS2-PtTe2 heterostructure, showing the orientationally aligned (100) and (110) planes of each material, indicating the epitaxial growth of the MoS2. j (left) High-angle annular dark-field scanning-TEM (HAADF-STEM) image demonstrating the atomic arrangements at the MoS2-PtTe2 heterojunction. (right) Schematic of the lateral heteroepitaxy aligned to the <100> direction.

As an efficient edge contact metal for MoS2, we selected one of 2D metallic TMDs, PtTe2, because it exhibits many attractive features as potential n-type metal contacts for 2D semiconductors. For example, the theoretical work function (WF) of few-layered PtTe2 (WF; ∼4.56–4.57 eV)22 is one of the smallest among those reported for chemically synthesizable metallic TMDs23,24,25 (Supplementary Fig. 1), and its electrical conductivity (>106 S/m) has shown to be the highest among 2D metals26,27. However, the simultaneous achievement of large-area production of high-quality stoichiometric, metallic TMD thin films with thermal stability remains challenging, mainly because of the difficulties in incorporating Te and low environmental stability during thermal CVD28,29. Furthermore, guaranteeing the thermal stability of the 2D metal is essential for our two-step CVD process because PtTe2 must resist the thermal procedure required for synthesizing of MoS2 while maintaining excellent quality. In this regard, no success has been achieved yet for 2D-2D lateral heterojunctions based on 2D tellurides.

Since Te vacancies substantially reduce the Gibbs free energy for the adsorption of ambient gas and cause structural instability30, the growth of high-quality PtTe2 is essential to ensure its stability to some extent. Thus, we synthesized the PtTe2 crystals using the eutectic solidification method26,31, where the pre-deposited Pt precursor reacted with liquefied Te at 700 °C (Fig. 1a). The resultant PtTe2 formed single crystals with a highly stoichiometric nature (Supplementary Fig. 2). As our synthetic methods do not require an oxide precursor, no oxygen-metal bonds, which often become reactive sites and cause poor stability, were formed32. In addition, the PtTe2 crystals maintained their high-quality structures with Te terminations even after exposure to air for up to ∼3 h, as indicated by TEM analysis (Supplementary Fig. 3). The WF of PtTe2 (∼4.65 eV), characterized by ultraviolet photoelectron spectroscopy (UPS), was comparable to the computed value22 (Supplementary Fig. 2h), satisfying the basic requirement of an efficient n-type contact for the MoS2 transistor, considering its band structure (Supplementary Fig. 1).

To evaluate the thermal stability of the as-synthesized PtTe2, the crystal was annealed under UHV conditions (∼10−10 Torr) at temperatures between T = 500–1000 °C for 1 h. The Raman spectra obtained are shown in Fig. 1c. The as-grown PtTe2 and the UHV-annealed crystals heated to 900 °C showed comparable Raman in-plane Eg (∼110 cm−1) and out-of-plane A1g (∼156 cm−1) vibrational modes of PtTe227 (black dashed line in Fig. 1c). Remarkably, only annealing above ∼1000 °C altered the peak positions and their intensities, demonstrating the high thermal stability of the PtTe2. The thermal stability is an intrinsic property independent of the thickness and degree of structure order, as evaluated by X-ray photoelectron spectrum (XPS) and UPS (Supplementary Fig. 4). The surface properties of PtTe2 start to change above the T of ∼825 °C, which is far beyond the limitations of metallic TMDs (e.g., WTe2, MoTe2, TaS2, and 1 T’-MoS2) measured under vacuum or in an Ar atmosphere32,33,34,35,36. In addition, low electrical resistivity of PtTe2 (ρ ≈ 0.37 mΩ·cm; Supplementary Fig. 5a, b), even lower than other few-layered metallic TMDs31,34,37,38,39 (ρ ≈ 0.5–100 mΩ·cm), shows promise for a robust electrode that may prevent thermal stress as summarized in Fig. 1d.

Following the synthesis of thermal-stable PtTe2 multilayers, a monolayer of MoS2 was formed laterally along the edge of the PtTe2 by CVD at ∼700 °C (Fig. 1b). Compared to the edge, the atomically pristine, dangling-bond-free surface of a 2D crystal typically possesses fewer surface defects and minimal MoS2 nucleation. Density functional theory (DFT) simulations were performed to investigate the selective nucleation of MoS2 on the edges of PtTe2. Adsorption energy calculations reveal that there was preferential adsorption and subsequent nucleation of MoS2 at the PtTe2 edge. For instance, the MoS2 monomer exhibited a lower adsorption energy of −3.6 eV at the PtTe2 edge compared to −2.7 eV on the PtTe2 basal plane (Supplementary Fig. 6). These findings are consistent with those of previous reports on the two-step CVD of 2D heterostructures, where in the adsorption energy of 2D TMDs at the edge of a 2D crystal was lower than that on the 2D basal plane19,40. The low occurrence of MoS2 nucleation on the PtTe2 surface is attributed to the higher adsorption energy of MoS2 nuclei on the basal plane. In our experiments, we significantly lowered the mass flux of precursors through the source-contact geometry and use of a MoOx thin-film precursor significantly reduced the opportunities for nucleation (Supplementary Note 1). The attachment of adatoms or atomic clusters of MoS2 by heterogeneous nucleation was allowed only at the edge of PtTe2. The introduction of a higher mass flux would thus increase the possibility of producing more nucleations41 and trigger the synthesis of randomly distributed multilayer MoS2 on the structures.

Attributed to the edge-mediated growth mode, the MoS2 crystals were observed exclusively along the PtTe2 edges as shown in false-colored scanning electron microscopy (SEM) images (inset of Fig. 1b and Supplementary Fig. 7). The Raman signals at the interface of MSJ demonstrated the strong signals of PtTe2 without variation in positions, while the MoS2 features of E2g (∼384 cm−1) and A1g (∼407 cm−1) modes also existed (Fig. 1e). Most of the MoS2 attached to PtTe2 was a monolayer with a uniform thickness of ∼0.7 nm, as shown in the AFM image and height profile (Fig. 1f). XPS analysis of the heterostructures was used to reveal the surface compositions and chemistries (Fig. 1g, h and Supplementary Fig. 8). The XPS spectra of the MoS2 layer did not show a substantial peak shift compared to that of non-stitched bare flakes (green, Fig. 1g, h). In comparison, the vertically deposited 3D metals on MoS2 can induce surface defects4,42, that is, a non-stoichiometric layer (i.e., MoxSy) or alloys (i.e., TixSy), as we experimentally demonstrated in the case of Ti/MoS2 (gray, Fig. 1g). Hence, the coincident binding energy of MoS2 connected to PtTe2 and that of the bare flakes suggests that the present growth mode conferred the intrinsic surface properties of the 2D semiconductor layer (i.e., MoS2), as the MoS2 layer was grown after preparing PtTe2.

XPS analysis further revealed no noticeable change in the stoichiometry of PtTe2 after thermal CVD for MoS2 (at. % (Te/Pt) ≈ 1.80). This high stability of PtTe2 during thermal CVD was also confirmed by SEM-EDS characterization (Supplementary Fig. 7d). Pt and Te were the only two observed elements, and there were no apparent variations in their stoichiometry (that is, averaged at. % (Te/Pt) = 1.90 ± 0.06). In addition, we electrically characterized PtTe2 to verify that the influence of the high-temperature process was negligible (Supplementary Fig. 5c, d). The sustained low ρ (≈ 0.35 mΩ·cm) and the weak dependence on gate voltage (Vg) imply that exposure to chemical species (MoOx and S) does not degrade PtTe2 (Supplementary Fig. 5d). Back-scattered SEM analysis did not show any traces of in-plane mixed alloying (Supplementary Fig. 7e–h), further demonstrating the high stability of PtTe2.

Structural analysis conducted using transmission electron microscopy (TEM) also confirmed the high quality of the PtTe2-MoS2 lateral heterostructure (Fig. 1i, j, and Supplementary Figs. 9–11). We found that the MoS2 monolayer grew epitaxially along the edge of PtTe2 single crystal using the selected area electron diffraction (SAED) pattern (Fig. 1i), indicated by the two aligned sets of hexagonal diffraction spots with six-fold symmetry reflecting the epitaxially aligned (110) and (100) lattice planes. Atomic-resolution analysis was performed using high-angle annular dark-field scanning-TEM (HAADF-STEM) (Fig. 1j). The 2H-MoS2 was atomically stitched to 1T-PtTe2 without void-like defects. The high stoichiometry and compositional consistency of PtTe2 were also confirmed by the STEM-EDS mapping and spectra (Supplementary Fig. 9a–f). The electron energy loss spectroscopy (EELS) line scan further revealed the abrupt compositional change at the junction (Supplementary Fig. 9g–i). Cross-sectional TEM analysis of synthetic MSJ also provided identical insight into the edge-to-edge connected structure, demonstrating in-plane epitaxial growth of MoS2 and sharp interface at the junction (Supplementary Fig. 10). Remarkably, the absence of mixed or alloyed structures in the as-synthesized MSJ implies that our synthesis approach was successful. This also demonstrates the merit of our approach compared to those adopted in previous studies14,16,18 (as summarized in Supplementary Table 1). Interestingly, the high density of dangling bonds at the PtTe2 edge generated several MoS2 basal planes that were attached vertically to the edges of the PtTe2 flakes (Supplementary Fig. 11). However, the vertical MoS2 layers were relatively insignificant in the synthesized results because most MSJs possessed laterally stitched components without vertical structures.

We performed DFT calculations to understand the formation mechanism of defect-free interface in the lateral PtTe2-MoS2 MSJ (Supplementary Fig. 12). The calculated relative energies (ΔE) of the possible intermediates (i.e., MoOx and S adsorbents) attached to the PtTe2 edge indicated the relative stability of each atomic structure during the epitaxial growth of MoS2 (Supplementary Table 2). We found that reactive gas-phase S atoms were bound to MoO3 precursor attached to the edge of PtTe2 (ΔE < −2.88 eV), and that O in MoO3 tended to desorb as it reacted with additional S by forming SO2(g) because of the consequent exothermic processes. A similar repeated reduction process for MoO3-x resulted in the formation of the most stable MoS2 structure because of the substantial energy relative to the initial structure (ΔE = −19.49 eV). Furthermore, each periodic interfacial cell comprised four PtTe2 and five MoS2 unit cells to minimize the lattice mismatch at the heterojunction (Supplementary Fig. 13). The lattice mismatch between PtTe2 and MoS2 was ∼18% when each unit cell of PtTe2 was matched to a unit cell of MoS2 in a one-to-one ratio according to the equation λ = (|a1 − a2 | )/a2, where a1 (∼3.25 ± 0.05 Å) and a2 (∼3.96 ± 0.05 Å) are the in-plane lattice constants of MoS243 and PtTe244, respectively (Supplementary Fig. 13a). In comparison, adjusting the number of unit cells on the interface to a five-to-four ratio of MoS2 and PtTe2 resulted in a smaller mismatch between the materials (∼3%). STEM analysis also validated our heterostructure with consistently matched periodic cells along the <100> direction, indicating a (semi-)coherent interface (Supplementary Fig. 13b–d). Given this smaller interfacial cell mismatch (∼3%), we calculated the most stable atomic structure for the heterostructure using DFT and the multicell model, as depicted in Supplementary Fig. 13b, c. The Pt-S and Mo-Te covalent bonds formed at the interface, resulted in strong orbital interactions between the atoms at the heterojunction.

High-performance monolayer MoS2 FETs with PtTe2 edge contact

We now shift our focus to the electrical characterization of the edge-contacted 2D-2D MSJ field-effect transistors (FETs). After the definition of MoS2 channels by the reactive ion etching process, PtTe2-flake-connected MoS2 MSJ FETs were fabricated by Ti/Au (10/70 nm) contact pad deposition on PtTe2. The Ti/Au layer was also deposited on the other side of the MoS2 channel to produce an asymmetrical contacted MoS2 channel with a fixed width (W) and length (L) for comparison with the MoS2-Ti vertical junction (Fig. 2a, b). The gate bias was applied through the 300-nm-thick SiO2 dielectric layer for this measurement. Because the reverse-biased contact (source) causes most of the voltage drop and dominates the transistor behavior in n-type MoS2 MSJ FETs, the source (either Ti or PtTe2) determines the performance of a FET with asymmetric contacts. This allows the electrical properties of the barrier to be systemically evaluated by controlling the interface15,29. We selected Ti as the counterpart to PtTe2 because it is the most widely used contact and has a low WF of ∼4.33 eV23, which is even smaller than that of PtTe2 (∼4.60-4.65 eV in Fig. 1g).

a–h Monolayer MoS2 FETs with asymmetric carrier injection from PtTe2 lateral epitaxial contact and from vertical Ti, characterized at room temperature. a Schematic and (b) optical microscopy image of a device with asymmetric Ti/Au and PtTe2 electrodes contacted to a monolayer MoS2 (white dashed lines) with a defined channel width (W) and length (L). c, e Cross-sectional illustrations of resistance networks of monolayer MoS2-based MSJ with (c) atomically stitched PtTe2 lateral contact and (e) top-contact with Ti/Au. Metallization of MoS2 can degrade both the contact resistivity (ρc) and sheet resistance (Rsh) of MoS2. In contrast, the PtTe2-MoS2 heterostructure has simpler resistance components, and the chemically derived edge resistance (Redge) is the only series resistance for the channel (Rch). d, f Comparison of band alignments with different Schottky barrier heights (SBHs) and Schottky barrier width (SBW) with respect to the MoS2 conduction band (CB) and valance band (VB) edges for (d) PtTe2-MoS2 heterostructure and (f) conventional 3D metal-contacted MoS2. Tunneling barrier formed by vdW gap between Ti and MoS2 (TvdW) and defect-induced deep levels are displayed in (f). g Drain current (Ids) as a function of gate voltage (Vg) for PtTe2-MoS2 (red) and Ti/MoS2 (blue) MSJ FETs on the logarithmic (lines; left) and linear (symbols; right) scales. h Summary of the field-effect mobility (μFE) and on-state current (Ion) of FETs with different carrier injections from PtTe2 (red) and Ti (blue). The error bars indicate the standard deviations from each device set. i, j SBH of PtTe2-MoS2 MSJ extracted using thermionic emission model. i Calculated thermionic barrier height of PtTe2-MoS2 (red) and Ti/MoS2 MSJ (blue) as a function of Vg showing the low SBH of 38.5 meV at the flat band voltage. Inset: representative Arrhenius plot (ln(Ids/T3/2) vs. 1/kBT) of PtTe2-MoS2 heterojunction with different Vg. j Comparison of the SBH of few-layer MoS2 based MSJ FETs with 3D top contacts (Ti47,48,49, Cr48, Ag49, Au48, and Pd48; solid) and with 2D lateral contacts (Mo2C15, and graphene16,17; open). The extracted SBHs of PtTe2-MoS2 (red) and Ti/MoS2 (blue) are indicated by colored symbols. Plots of the strength of Fermi-level pinning (S = |d(SBH)/d(WF)|) are shown as solid lines in order to compare the mechanism of formation of the SBHs.

Figure 2g shows a representative transfer characterization (Ids-Vg) of the MSJs where the electrons were injected from the PtTe2 edge (red) and the vertical Ti contact (blue). In addition to the output curve (Supplementary Fig. 14a), the on-state current (Ion) of PtTe2-MoS2 (∼4.0 μA/μm) was twice that of Ti-MoS2 (∼1.8 μA/μm). The two-terminal field-effect mobility (μFE) was also increased to ∼9.7 cm2 V−1 s−1 by injection of charge carriers from PtTe2, compared to Ti (∼7.0 cm2 V−1 s−1) for the same channel (∼3.5 ± 1.3 cm2 V−1 s−1 and ∼1.6 ± 0.9 cm2 V−1 s−1 on average for more than 10 devices with PtTe2 and Ti asymmetric contacts, respectively; and the averaged values are demonstrated in Fig. 2h). We found a slight negative shift of the turn-on voltage when the PtTe2 source electrode was selected. This negative shift reflects the improved carrier injection from the contact45,46 because the reduced Rc and SBH caused the transistor easier to switch on (note that we could not observe an obvious doping effect on the in the XPS (Fig. 1g, h) and Raman spectra (Fig. 1e) after lateral epitaxy of PtTe2). The performance enhancement was also confirmed for the MoS2 FET with symmetric contact geometry (i.e., PtTe2-MoS2-PtTe2; Supplementary Figs. 14b–e). It showed a μFE of ∼15.8 cm2 V−1 s−1, higher than those from asymmetrically contacted FET, which again verifies the influence of the resistance of the FET components related to Ti.

High-energy deposition of a 3D metal typically degrades the surface of monolayer MoS2 by forming sulfur vacancies and promoting atomic diffusion at MSJs4,42 (i.e., forming interfacial defects of Ti/MoS2 as shown in Fig. 1g, h). These processes increase the Rsh and contact resistivity (ρc) by forming localized states as depicted in the contact components in Fig. 2e, f29,47,48,49. In addition, the established gap states can shift the charge neutrality, pinning the Fermi level to the mid-gap of MoS2, which can significantly impact the Schottky barrier height (SBH)48,50. According to Sze’s model51, the Fermi level pinning (FLP) strength increases with the density of interfacial traps (Dit; Supplementary Fig. 15 and Supplementary Note 2); thus, the large Dit in our Ti/MoS2 MSJ FETs could induce strong FLP to the mid-gap states, and therefore resulted in a large SBH and lower thermionic emission efficiency over the SB. Furthermore, the top contact scheme has a long path for carrier transfer (e.g., wide width of the barriers, BW), leading to a larger Rsh and ρc. The vdW gap between the 3D metal and 2D semiconductor can also produce an additional tunnelling barrier (TvdW), although Ti/MoS2 may possess a narrower TvdW than other 3D metals/MoS2 because of the strong hybridization2,42. In contrast, the PtTe2-MoS2 MSJ developed herein has a cleaner interface that prevents further metallization on the MoS2 surface (i.e., absence of Rsh), leading to simple contact components only related to the edge (Fig. 2c, d)5,11. The absence of TvdW and the reduced BW can improve carrier injection through the edge of PtTe2. Notably, despite the presence of a vdW gap between PtTe2 and the metal contact pad (i.e., Ti/Au in Fig. 2a), the contribution of Rc in the Ti/PtTe2 interface (∼0.12–0.23 kΩ·μm) of the MoS2-based MSJ system was insignificant (∼0.13%; Supplementary Fig. 16). Furthermore, the estimated Rc of the Ti/PtTe2 interface is almost the lowest value that can be obtained in a 3D metal/vdW metal interfacial system (Supplementary Table 3) and is even smaller than that obtained with the most widely used vdW metal (graphene).

To gain insight into the physical characteristic associated with carrier transport through the barriers, the thermionic barrier heights (ϕB) of the monolayer MoS2 MSJ FETs with symmetric contacts of PtTe2 and Ti were calculated by electrical characterization at low temperatures (Fig. 2i, j and Supplementary Fig. 17). This allowed us to extract the SBHs at the interface by fitting the Arrhenius plot to the thermionic emission model48:

Here, A is the junction area, and A* is the effective Richardson–Boltzmann constant. According to Eq. (1), the ϕB can be extracted from the slope of the Arrhenius plot (inset of Fig. 2i), resulting in ϕB as a function of Vg (Fig. 2i). Interestingly, the ϕB for PtTe2-contacted MSJ at the flat band voltage (VFB) was found to be a substantially small value of ∼35.9 ± 9.8 meV (average of four devices), where the primary carrier injection mechanism changed from the thermionic transport (Vg < VFB) to tunneling (Vg > VFB, where the linear Vg-ϕB relation ends at this actual SBH). For Vg values exceeding ∼30 V, ϕB was negative, indicating tunneling-dominant electrical transport through the reduced SBW of the edge contact, which is difficult to achieve with the 3D metal contact owing to the wider BW and the presence of TvdW for the latter. For example, the SBW at the PtTe2-MoS2 interface (∼0.94 nm) calculated using a classical model for Schottky diodes was smaller than that of the Ti/MoS2 MSJ FETs (∼1.5 nm) (Supplementary Note 2).

The extracted SBH (ϕBat VFB) of ∼35.9 meV is considerably lower than that of the Ti/MoS2 MSJ (∼125 meV) and almost one order of magnitude smaller than previously reported values for other 3D-metal/MoS2 MSJ47,48,49 (≈100–500 meV in Fig. 2j). Deep energy level states were established primarily because the interface was degraded by penetration of the 3D metals into the MoS2 band29,47,48,49 (Fig. 2f). Therefore, the SBH of the FETs with Ti contact was much higher than the ideal value calculated by applying the Schottky-Mott rule (e.g., SBH = WF – χ ≈ 0 meV, where χ is the electron affinity of monolayer MoS2 (≈ 4.28 eV)48). The deviation from the Schottky-Mott rule is substantial for 3D contacts; thus, SBHs cannot be effectively modulated by selecting the 3D metals, as the Fermi levels are pinned to the shifted charge-neutral level (CNL). The interface index, S (=|d(SBH)/d(WF)|), indicates the extent of the deviation48, which approaches zero for the 3D metal contacts (blue line in Fig. 2j). This strong FLP (S ≈ 0) agrees well with the theoretical model prediction51 that the S value decreases with increasing interfacial defect density (Dit ≈ ∞). We found that the increase in Dit due to the replacement of the edge PtTe2 by a top Ti contact could approach ∼1.13 × 1013 eV−1 cm−2, and gave rise to a stronger FLP (Supplementary Fig. 15 and Supplementary Note 2).

Compared with vertical 3D metal contacts, the synthetic edge contact can weaken the FLP because of the lowered dimensionality with fewer interfacial defects10,13,50,52 Hence, the SBHs can follow the ideal Schottky-Mott limit to some extent (S = 1; red line in Fig. 2j), enabling the formation of tiny SBHs by using low-WF 2D metals. Furthermore, the impact of strong covalent bonds at the edge interface, which may result in a slight deviation from the perfect Schottky-Mott limit through the formation of a metal-induced gap state (MIGS)13, is less significant compared to that at the top contacts because of the 1D-like atomically thin interface (Supplementary Fig. 18). Accordingly, the SBH in all 2D lateral contacts (Mo2C15, and graphene16,17) to few-layer MoS2 MSJ FETs produced by CVD (∼26-45 meV) is much smaller than those of vertical 3D contacts (Fig. 2j). Similarly, the FLP-free PtTe2 edge interface allowed the achievement of a negligible SBH (∼35.9 meV) due to low WF of PtTe2 (∼4.56 eV22); this is one of the lowest WF values among 2D metals, as summarized in Supplementary Fig. 1. This smaller SBH (∼35.9 meV) enabled improved thermionic emission and tunneling transport through the SB compared with the top-contact Ti/MoS2, which had a higher SBH (∼135 meV) and additional TvdW. A higher μFE and on/off ratio was therefore achieved, as indicated by variation of carrier transport through the barriers with Vg (Supplementary Fig. 19).

Spatial arrangement of synthetic edge contacts

As the ultimate approach for demonstrating the advantage of PtTe2 with respect to material processing, we eventually controlled the spatial arrangement of the synthetic edge contacts at the microscopic level (Fig. 3a). Powder-based tellurization was used to transform the Pt patterns prepared by conventional photolithography into PtTe2 patterns at a low temperature of ∼400 °C (here, we used Pt instead of PtOx, which can assure high quality of the resultant PtTe232). Remarkably, the patterns were successfully manufactured on a 2-inch SiO2/Si wafer, which is vital for achieving scalable, mass production of PtTe2 electrodes in any desired shapes (Fig. 3b). The electrical characterization by the four-point probe method showed that the Rsh of the as-synthesized PtTe2 thin film was H-dependent due to the greater carrier scattering as H decreased (Fig. 3c). The Rsh values of the developed PtTe2 samples were lower than those previously reported for CVD-grown films53, and comparable to those of single-crystalline flakes27, suggesting that the developed films are of high quality. We found that the XPS-extracted stoichiometries for 4-nm-thick PtTe2 were almost perfect (at.% ratio of Te/Pt ≈ 2) independent on the thermal stress up to T ≈ 825 °C (Fig. 3d), suggesting the high quality and thermal stability of the film (similar to the case for single crystals in Fig. 1). The Rsh of the PtTe2 thin film was also ∼450 Ω/sq for the samples annealed below 800 °C. However, it suddenly changed as T reached 850 °C (Rsh ≈ 208 Ω/sq), indicating the atomic displacements of Te (which begins to resemble the electrical properties of Pt, as noted in caption of Supplementary Fig. 4).

a Schematic of procedure for realizing PtTe2-MoS2 heterostructure arrays in a position-controllable manner, involving photolithography before the tellurization of Pt. b Photograph image of as-grown large-scale PtTe2 patterns on a 2-inch-scale SiO2/Si substrate (left), and representative OM images of the thin film captured on the left image (right). c Sheet resistance (Rsh) of as-grown PtTe2 thin film as a function of the film thickness (H), characterized by four-probe method. Rsh values for high-quality PtTe2 from previous reports27,53 are displayed for comparison. The inset shows a representative AFM image of the as-grown thin film (scale bar: 1 μm). d (left) XPS-derived atomic ratio of the thin film, showing the nearly ideal stoichiometry of PtTe2 (at. % (Te/Pt) ≈ 2; dashed red line) irrespective to T up to 825 °C, (right) Rsh of thin films as a function of annealing T, with Rsh ~467 Ω/sq (for T = 500 °C) indicated with a blue dashed line. e Representative OM images of MoS2 monolayer laterally contacted to the edge of polycrystalline PtTe2 thin film patterns with H ≈ 4 nm, in the form of fully stitched thin film depending on the growth conditions. f Representative Raman spectrum of PtTe2-MoS2 heterostructure, showing strong signals of each material, e.g., Eg (110.2 cm−1) and A1g (156.5 cm−1) peaks of PtTe2 and E2g (384.5 cm−1) and A1g (402.3 cm−1) modes of MoS2. g, h TEM analysis of heterostructure with patterned PtTe2 (H ≈ 4 nm) and monolayer MoS2. g HAADF-STEM image of heterostructure showing epitaxially stitched PtTe2 and MoS2 without void-like defects along both surfaces. h Diffractogram corresponding to interface region, indicating orientationally aligned (100) and (110) planes in each atomic structure.

Subsequent conducted thermal CVD of MoS2 induces lateral epitaxy of monolayer MoS2 from the edge of the arranged PtTe2 patterns (Fig. 3e). A key to achieving a fully stitched MoS2 thin film between the PtTe2 crystals (instead of small flakes) is the extension of the growth time while decreasing the deposition rate via delicate control of the atomic flux. A higher growth temperature (>730 °C) and extensive precursors (for MoOx and S) resulted in multilayer MoS2 and alloyed MoS2/PtTe2 structures due to the island growth mode, whereas the layer-by-layer growth mode was enabled by the opposite manner. Figure 3f shows a representative Raman spectrum of the heterojunction, which shows the vibrational modes of each layered crystal. The Raman peaks for MoS2 in the flakes and at the interface did not differ significantly (e.g., the energy difference between E2g and A1g peaks ≈ 19 cm−1), suggesting the growth of monolayer MoS2. The HAADF-STEM image (Fig. 3g) and its indexed diffractogram (Fig. 3h) confirm epitaxial alignment between monolayer MoS2 and PtTe2. The STEM(-EDS) and corresponding (inverse) FFT study also verified the formation of a well-stitched lateral heterojunction comprising high-quality atomic layers (Supplementary Fig. 20). We did not find any significant differences from the bare MoS2 flake in the XPS characterization of MoS2 grown along the PtTe2 array (Supplementary Figs. 8c, d).

Transport in the edge-contacted PtTe2-MoS2 MSJ FET arrays

Arrays of FETs composed of edge-contacted MSJs patterns were fabricated and operated by using an Al2O3 back-gate dielectric (Fig. 4a). Analysis of the output and transfer characteristics (Fig. 4b, c) showed that the monolayer MoS2 FETs with PtTe2 symmetric contacts exhibited a maximum μFE value of ∼17.9 cm2 V−1 s−1 (∼10.6 ± 2.9 cm2 V−1 s−1 on average), Ion of up to ∼3.4 μA/μm (∼2.3 ± 0.3 μA/μm) and Ion/Ioff in the range of ∼107 to 108, which are much higher than those fabricated using vertical Ti contacts on monolayer MoS2 FETs with the same device geometries (channel L and W). We repeatedly observed performance enhancement for a large number of devices (>15), where the averaged μFE of the Ti/MoS2 FET was ∼0.4 ± 0.3 cm2 V−1 s−1 and the Ion was ∼0.2 ± 0.1 μA/μm (Fig. 4d). It is worthwhile to note that, considering their L and LT values, the μFE value of the MoS2 FETs with PtTe2 edge contacts were either comparable or even higher than those of previously reported devices with various 3D edges (e.g., Sc54, Ti50, Au10, and Mn13) or 2D lateral contacts (e.g., graphene (Gr.)17,18,55,56, and VS214) (Supplementary Figs. 21a–c).

a Schematic showing monolayer MoS2 FETs with patterned PtTe2 edge contacts (upper) and vertical Ti contacts (lower). The transfer length (LT) of the carrier and physically attained contact length (Lc) are schematically demonstrated. b Representative Ids–Vds characteristics of monolayer MoS2 FET with symmetric PtTe2 and Ti contact electrodes depending on Vg. c Ids–Vg characteristics of corresponding devices on linear (symbols; right) and logarithmic scale (lines; left). d Average μFE and Ion of different FETs (>15 devices) contacted to PtTe2 (red) or Ti (blue). The error bars indicate the standard deviations of each measurement set. e–g Determination of contact resistance (Rc) of MSJs with different compositions using (e, f) TLM and (g) Y-function method. e TLM plot showing total resistance normalized by contact width (RW) as a function of L. The y-intercept yields the 2Rc in units of Ω ∙ μm. Inset shows OM image of MoS2 (purple-like) grown between edges of PtTe2 patterned for TLM. (f) TLM-derived Rc of PtTe2-MoS2 MSJ FETs approaching ~168 ± 127 kΩ∙μm when the carrier density (n2D) of ~9 × 1012 cm−2 was largely induced by Vg (red circles), which is significantly lower than that of Ti/MoS2 (~4,285 ± 1,959 kΩ∙μm, blue squares). Solid lines specify curves fitted to the relation of Rc depending on the n2D (Rc ∝ n2D−0.5)2. g Histograms of Rc for PtTe2-MoS2 (left) and Ti/MoS2 MSJ FETs (right) extracted by the Y-function method (Supplementary Fig. 22). The lowest Rc of PtTe2-MoS2 obtained in this study was ~18.2 kΩ·μm and the average value reached ~113.0 ± 60.3 kΩ·μm. h Benchmark specific contact resistivity (ρc) and LT of synthetic PtTe2 contacts. The experimental data from MoS2 FETs with lateral graphene contact (Gr.16,55), 3D edge contacts (Ti11, Ni5, Au10, Sc54, and Mn13), and top contacts (Ti6,58, Ni59, Au7,10, Ag9, and Mn13) are demonstrated. The colored symbols are the extracted data for PtTe2 (red stars) and Ti (blue circle) in this work. For fair comparison, the data are sorted by ρc extraction methods, i.e., four-point probe (open), TLM (solid), and Y-function (half-open symbol).

To determine whether the μFE of a device was severely underestimated because of the contact property, we extracted the intrinsic mobility (μ0) of more than 30 different devices using the Y-function method (Supplementary Fig. 22). The μ0 value is typically free from underestimation due to Rc and provides a better indication of the intrinsic performance11,55,57. The averaged μ0 value in our PtTe2-MoS2 MSJ FETs was calculated to be ∼11.1 ± 4.5 cm2 V−2 s−1, which is almost comparable to the μFE values (∼10.6 ± 2.9 cm2 V−2 s−1) calculated using the transconductance (gm = ∂Ids/ ∂Vg). The insignificant difference between μFE and μ0 (∼4.5%) implies the presence of a minor contact barrier at the edge interface.

Notably, by using a MSJ fabricated with transfer length method (TLM) patterns, we could determine the Rc values of the monolayer MoS2 FETs with PtTe2 edge contact (Fig. 4e, f). The TLM-driven Rc reached ∼168 ± 127 kΩ·μm when a carrier density (n2D) of ∼9 × 1012 cm−2 was attained, which was largely induced by a Vg of ∼19 V. This Rc value is ∼25 times lower than that of its counterpart using Ti (∼4,285 ± 1,959 kΩ·μm) in Fig. 4f. We note that the demonstration of Rc as a function of n2D (= Cox(Vg-Vth)/q) helps compare devices because n2D includes information on the threshold voltage (Vth) that can be varied by channel doping, the gate dielectric layer, and the interfacial trap density of the substrate2,6,7. The Rc was also calculated using the Y-function method11,55,57 (Fig. 4g and Supplementary Fig. 22), where the minimum Rc of the device was ∼18 kΩ·μm (∼113 ± 60 kΩ·μm, on average) and ∼2,562 kΩ·μm (∼12,443 ± 8,406 kΩ·μm) for PtTe2-MoS2 and Ti/MoS2, respectively. The average Rc values were comparable to those extracted from the TLM, demonstrating the reliability of the characterization methods. The low Rc obtained with PtTe2 allowed the FETs to outperform the Ti/MoS2 MSJ FETs (Fig. 4b–d).

The significantly low TLM-driven Rc at the monolayer-thick interface (e.g., LT ≈ 0.7 nm) of the spatially-arranged PtTe2-MoS2 MSJ suggests that the contact length (Lc) can be further scaled without an increase in Rc (Fig. 4h), as an advantage. For 3D top contacts, Rc increases as the Lc decreases below the LT because current crowding becomes severe, according to the transmission line model6,7 expressed as Rc = \(\sqrt{{\rho }_{c}{R}_{{sh}}}\)cot(Lc/LT), where LT = \(\sqrt{{\rho }_{c}/{\rho }_{{sh}}}\) and ρc (= Rc ∙ LT) is the specific contact resistivity (Supplementary Fig. 23). Thus, there have been tremendous efforts (i.e., insertion of an interlayer6, chemical doping58,59, and metal deposition under UHV conditions7) to achieve immunity of Rc to Lc scaling by lowering both ρc and LT (right panel in Fig. 4h). However, the achievement of a small LT (< tens of nanometers) together with low ρc is inherently challenging for 3D top contacts8,9,10. Instead, the edge contact can prospectively afford a negligible LT because carrier transport occurs strictly through the interface of the edge5,11,13 as depicted in Fig. 4a.

We summarize the device performances of MoS2 FETs with 3D edge5,10,11,13,50,54 or 2D lateral contacts14,15,16,17,18,55,56 (Supplementary Table 5). Although a direct comparison of the contact properties with our device is inappropriate because of the differences in the LT values, MoS2 channel thicknesses, and Rc-extraction methods (see Supplementary Note 3 for more details), the developed PtTe2-MoS2 MSJ had a significantly low ρc (as low as ∼11.7 Ω·μm2) and LT ≈ 0.7 nm, which is the lowest value among those reported for few-layer MoS2 FETs with 2D lateral graphene16,55, or 3D edge (Ti11, Ni5, Au10, Sc54, and Mn13) contacts (see the left panel in Fig. 4h and Supplementary Fig. 21d), thus promising the realization of ultralow Rc in Lc-scaled transistors for next-generation 2D nanoelectronics. We propose that even further reduction of Rc and SBH is possible in our PtTe2 edge contact by achieving a multilayer lateral 2D-2D MSJ heterostructure, which can be attributed to the effectively screened interfacial traps from the substrates13,60, the downshift of the conduction band edge in multilayer MoS229, and the weaker current crowding at the thicker heterointerface6,7,8,9,10,13. Moreover, the use of high-k dielectrics (e.g., HfO2, Sb2O3, SrTiO3), passivation layers (e.g., BN), and top-gate structures, which were already applied in the previous edge-contact FETs10,11,13,18,55, can also improve the performance of our device, which can be due to the suppressed charge scattering and trapped states from surrounding disorders60.

Discussion

We report here a spatially-controlled, reproducible preparation of metallic vdW PtTe2 crystals as a lateral edge contact with semiconducting monolayer MoS2. The high-quality stoichiometric PtTe2 retained its surface properties even after CVD at the high temperature of ∼750 °C under UHV conditions. The edge of thermally stable PtTe2 provides nucleation sites for the subsequently grown 2D semiconductor without noticeable thermal degradation, resulting in in-plane lateral MSJs without substantial interfacial issues such as alloying or void-like defects. Therefore, the PtTe2-MoS2 MSJ may have a simple resistance network and displays superior n-type carrier transport through the short and narrow thermionic barriers, enabling the higher performance of the FET compared to that composed of vertical 3D contacts. This approach also provides a more scalable way to produce an arrangement of lateral heterostructures in a dimension-controlled manner, where the contact properties could be evaluated by using the TLM patterns consisting of the lateral MSJ. The substantially small contact resistivities achieved through the atomically thin edge suggest that the developed contact scheme has the potential for scaling the contact length for miniaturized 2D electronics.

Our work on the synthesized edge-contact MSJ arrays offers benefits in terms of scalability for both material synthesis and device fabrication. The edge contact between 2D (or 3D) metals and 2D semiconductors should be developed and evaluated based on CVD-grown 2D layers to investigate its practical potential for semiconductor technology in the future. However, almost all investigations on lateral MoS2-based MSJs have drawbacks in terms of reproducibility or the achievement of pure edge contact (Supplementary Table 4). In this regard, our strategy based on direct growth of a large-area 2D metal on a dielectric substrate followed by MoS2 epitaxy has considerable advantages over other methods using 2D metals such as Mo2C15 and graphene16,17,18,55,56, formed by mechanical exfoliation of single crystal and/or transfer of CVD-grown layers. More importantly, the realization of pure edge contacts with the LT reduced to ∼1 nm using graphene16,17,18,55,56 or VS214 is highly challenging because of the inevitable laterally overlapped junction or alloyed structures.

In addition, the construction of TLM patterns using a TMD-based synthetic edge contact provides assurance by permitting a better systematic analysis. Because of the complexity of realizing a lateral MSJ, it is difficult to achieve reproducible data from multiple devices and to perform statistical computations for Rc10,11,13,14,15,16,18,54,55. Investigating Rc of edge-contact MSJs using TLM pattern proves particularly challenging because of channel-to-channel variations and deficiencies in integration scalability. Many of the studies on lateral MSJ rely on the four-point measurement10,13,14,15,16,18,54 or Y-function methods11,55 for Rc extraction, which can be inaccurate compared with the TLM (Supplementary Note 3). Therefore, together with the reproducibility of our 2D material system, the statistical analysis of the Rc values extracted by TLM and the Y-function method in this study can provide better insights into the electrical features of 2D-2D edge contacts.

Methods

Growth of PtTe2 flakes

The growth of multilayer PtTe2 single crystals was conducted using a conventional horizontal furnace system, in which the Te-Pt precursors on a SiO2/Si substrate were placed inside the center of the chamber. To prepare the precursor sample, a Pt thin film precursor (∼2 nm, 99.9% purity pellet) was deposited using an e-beam evaporator (Temescal FC-2000), and then 0.1 g of Te powder was introduced manually to cover up the thin film. The reactant was then heated to ∼700 °C (at a heating rate of ∼50 °C/min) under a pressure of ∼0.1 Torr using H2 (10 sccm) as the carrier gas. After maintaining a growth temperature of ∼700 °C for 1 min, the furnace was naturally cooled to room temperature. We succeeded in synthesizing PtTe2 directly on top of the SiO2/Si substrate because the unreacted Te was vaporized and sucked out toward the vacuum pump.

Preparation of patterned PtTe2 thin films

The pre-deposited, poly-crystalline Pt thin film (∼1 nm) on the SiO2/Si substrate and Te powder (∼0.1 g) inside a quartz boat were placed in a horizontal furnace ∼1 cm apart. Under low pressure (0.1 Torr) at ∼400 °C, the evaporated Te vapor reacts with the Pt precursor, resulting in a homogenous, uniform PtTe2 layer with a thickness of ∼4 nm. The thickness of the as-grown thin film could be controlled by modulating the Pt precursor’s thickness. For position-controllability, the shape of any desired pattern was defined using photolithography (MIDAS MDA-400S) with a photoresist with an undercut profile (DPRi-1549), followed by Pt deposition and lift-off. Using the same method for thin films, the shaped Pt precursor could be tellurized, resulting in successful growth of the PtTe2 patterns.

Synthesis of MoS2 along the edge of PtTe2

The MoS2 flakes were synthesized using MoO3 thin film (∼1 nm-thick on a 1 cm2 SiO2/Si substrate, evaporated using an e-beam evaporator) and S powder as precursors in atmospheric-pressure two-zone CVD with Ar/H2 as the carrier gas. To promote the nucleation of MoS2, ∼1 μL of a 0.01 M NaCl promoter solution was pipetted on the corner of the oxide thin film on the substrate. Then, the NaCl solution was baked at ∼100 °C to evaporate the water entirely. The formerly prepared PtTe2 multilayers on the substrate were placed face to face on top of the MoO3 film prepared with NaCl. This metal oxide/PtTe2 sample was placed at the center of the heat zone of the furnace, with the S-powder-containing boat loaded upstream of the CVD furnace. Under an Ar/H2 ratio of 70/20 sccm, the system was steadily heated to ∼700 °C. At a growth temperature of ∼700 °C, S vapor was introduced because the powder was heated at ∼200 °C just before reaching the growth temperature and then maintained constantly for a growth time of ∼10 min. The as-synthesized PtTe2 sample was stored in a chamber under UHV atmosphere (∼1010 Torr) immediately after synthesis, and the air exposure time of PtTe2 until the subsequent CVD process was <5 min.

Structural characterization

The morphological investigation was conducted using an SEM (Hitachi S-4800 or Su8220) equipped with high- and low-angle BSE detectors. Micro-Raman measurements were performed with a 532 nm laser (Thermo Scientific DXR2 Raman Microscope) configured for wavenumber precision of ≤0.066 cm−1. XRD patterns were captured using a Bruker AXS D8 instrument with a Cu Kα source. AFM images were recorded on a Bruker Dimension AFM operating in tapping mode. High-resolution STEM images, SAED patterns, EDS were obtained using an aberration-corrected FEI Titan3 G2 60-300 equipped at an acceleration voltage of 200 kV. Noises of high-resolution STEM images were subtracted by Wiener filter. EELS was performed using a Gatan Quantum 965 dual EELS system with an energy resolution of 1.0 eV under an acceleration voltage of 200 kV. Specimen for cross-section TEM analysis were prepared by focused ion beam (FEI Helios Nanolab 450HP). XPS and UPS measurements were performed using an ESCALAB 250XI system (ThermoFisher K-alpha) equipped with an Al X-ray source under UHV conditions. The calibration of the XPS was performed by the alignment of the C 1 s spectrum (whose binding energy is 284.5 eV).

DFT calculation

We constructed a 4 × 4 × 1 PtTe2 supercell with vacuum along the b and c directions to model a PtTe2 single layer strap with an edge having 50% Te coverage. We performed geometry optimization based on DFT calculations using the supercell and the Vienna ab initio software packet61 (VASP) code. We employed the projector-augmented-wave (PAW) method62 and the Perdew-Burke-Enzerhof (PBE) functional63 using a plane-wave basis set with an energy cutoff of 500 eV. The k-points were sampled using a 4 × 4 × 1 Monkhorst-Pack mesh64, and the spin-orbit coupling effect was also included.

Electrical device fabrication and measurements

To define the device channel, the shape of the channel layer was defined by e-beam lithography (NBL and NB3), and then a reactive ion etching process was conducted using SF6 and O2 plasma. The etched structures were transferred to a dielectric layer on highly p-doped Si, which can be used as the back-gate. For instance, the single-crystalline PtTe2-MoS2 MSJ was transferred to a 300-nm-thick SiO2 layer, whereas the conformally grown array was transferred to a 50-nm-thick Al2O3 layer. The well-connected heterointerface between PtTe2 and MoS2 confirmed through TEM analysis (Figs. 1j and 3g), proves that the wet transfer method utilizing a polymeric supporting layer did not affect the edge contact of the samples. The SiO2 layer was dry-oxidized in a furnace (KHD-306) with ±3% uniformity, and the Al2O3 dielectric layer was prepared by atomic layer deposition (Lucida, D100), being deposited within ±2% uniformity along the wafer. Ti/Au (∼10 and ∼70 nm, respectively) contacts and pads were then deposited using e-beam lithography and an e-beam evaporator. Electrical characterizations at different temperatures (138-300 K) were performed using a Keithley 4200-SCS detector in a cryogenic probe station (Lakeshore CRX-4K) under a high vacuum (∼10−6). The μFE of the FETs on the Al2O3 dielectric insulator were determined by measuring the gate oxide capacitance per unit area (Cox) of Al2O3 via C-V analysis of the metal-insulator-semiconductor structure (e.g., Pt/Al2O3/p++Si), where the DC voltage was swept from −5 to 10 V, while an AC voltage with an amplitude of ∼100 mV and frequency of ∼20 kHz was applied. The calculated Cox in the accumulation region was 0.164 ± 0.001 μF cm−2 (average of ten devices), which corresponds to an equivalent oxide thickness of ∼117.9 nm.

Data availability

Relevant data supporting the key findings of this study are available within the article and the Supplementary Information file. All raw data generated during the current study are available from the corresponding authors upon request.

References

Liu, C. et al. Two-dimensional materials for next-generation computing technologies. Nat. Nanotech. 15, 545–557 (2020).

Allain, A., Kang, J., Banerjee, K. & Kis, A. Electrical contacts to two-dimensional semiconductors. Nat. Mater. 14, 1195–1205 (2015).

International Roadmap for Devices and Systems: 2020 Edition, Executive Summary. (IEEE, 2020).

Liu, Y. et al. Approaching the Schottky–Mott limit in van der Waals metal–semiconductor junctions. Nature 557, 696–700 (2018).

Cheng, Z. et al. Immunity to Contact Scaling in MoS2 Transistors Using in Situ Edge Contacts. Nano Lett. 19, 5077–5085 (2019).

Andrews, K., Bowman, A., Rijal, U., Chen, P.-Y. & Zhou, Z. Improved Contacts and Device Performance in MoS2 Transistors Using a 2D Semiconductor Interlayer. ACS Nano 14, 6232–6241 (2020).

English, C. D., Shine, G., Dorgan, V. E., Saraswat, K. C. & Pop, E. Improved Contacts to MoS2 Transistors by Ultra-High Vacuum Metal Deposition. Nano Lett. 16, 3824–3830 (2016).

Liu, H. et al. Switching Mechanism in Single-Layer Molybdenum Disulfide Transistors: An Insight into Current Flow across Schottky Barriers. ACS Nano 8, 1031–1038 (2014).

Yuan, H. et al. Field effects of current crowding in metal-MoS2 contacts. Appl. Phys. Lett. 108, 103505 (2016).

Moon, B. H. et al. Junction-Structure-Dependent Schottky Barrier Inhomogeneity and Device Ideality of Monolayer MoS2 Field-Effect Transistors. ACS Appl. Mater. Interfaces 9, 11240–11246 (2017).

Jain, A. et al. One-Dimensional Edge Contacts to a Monolayer Semiconductor. Nano Lett. 19, 6914–6923 (2019).

Zhang, Y. et al. Edge-Epitaxial Growth of 2D NbS2-WS2 Lateral Metal-Semiconductor Heterostructures. Adv. Mater. 30, 1803665 (2018).

Choi, H. et al. Edge Contact for Carrier Injection and Transport in MoS2 Field-Effect Transistors. ACS Nano 13, 13169–13175 (2019).

Leong, W. S. et al. Synthetic Lateral Metal-Semiconductor Heterostructures of Transition Metal Disulfides. J. Am. Chem. Soc. 140, 12354–12358 (2018).

Jeon, J. et al. Epitaxial Synthesis of Molybdenum Carbide and Formation of a Mo2C/MoS2 Hybrid Structure via Chemical Conversion of Molybdenum Disulfide. ACS Nano 12, 338–346 (2018).

Ling, X. et al. Parallel Stitching of 2D Materials. Adv. Mater. 28, 2322–2329 (2016).

Behranginia, A. et al. Direct Growth of High Mobility and Low-Noise Lateral MoS2–Graphene Heterostructure Electronics. Small 13, 1604301 (2017).

Zhao, M. et al. Large-scale chemical assembly of atomically thin transistors and circuits. Nat. Nanotech. 11, 954–959 (2016).

Zhang, Z. et al. Epitaxial Growth of Two-Dimensional Metal–Semiconductor Transition-Metal Dichalcogenide Vertical Stacks (VSe2/MX2) and Their Band Alignments. ACS Nano 13, 885–893 (2019).

Wang, B. et al. Bifunctional NbS2-Based Asymmetric Heterostructure for Lateral and Vertical Electronic Devices. ACS Nano 14, 175–184 (2020).

Bertolazzi, S. et al. Engineering Chemically Active Defects in Monolayer MoS2 Transistors via Ion-Beam Irradiation and Their Healing via Vapor Deposition of Alkanethiols. Adv. Mater. 29, 1606760 (2017).

Shawkat, M. S. et al. Large-area 2D PtTe2/silicon vertical-junction devices with ultrafast and high-sensitivity photodetection and photovoltaic enhancement by integrating water droplets. Nanoscale 12, 23116–23124 (2020).

Liu, Y., Stradins, P. & Wei, S.-H. Van der Waals metal-semiconductor junction: Weak Fermi level pinning enables effective tuning of Schottky barrier. Sci. Adv. 2, e1600069 (2016).

Majidi, L. et al. New Class of Electrocatalysts Based on 2D Transition Metal Dichalcogenides in Ionic Liquid. Adv. Mater. 31, 1804453 (2019).

Shen, T., Ren, J.-C., Liu, X., Li, S. & Liu, W. van der Waals Stacking Induced Transition from Schottky to Ohmic Contacts: 2D Metals on Multilayer InSe. J. Am. Chem. Soc. 141, 3110–3115 (2019).

Hao, S. et al. Low-Temperature Eutectic Synthesis of PtTe2 with Weak Antilocalization and Controlled Layer Thinning. Adv. Funct. Mater. 28, 1803746 (2018).

Ma, H. F. et al. Thickness-Tunable Synthesis of Ultrathin Type-II Dirac Semimetal PtTe2 Single Crystals and Their Thickness-Dependent Electronic Properties. Nano Lett. 18, 3523–3529 (2018).

Yun, S. J. et al. Telluriding monolayer MoS2 and WS2 via alkali metal scooter. Nat. Commun. 8, 2163 (2017).

Song, S. et al. Wafer-scale production of patterned transition metal ditelluride layers for two-dimensional metal–semiconductor contacts at the Schottky–Mott limit. Nat. Electron. 3, 207–215 (2020).

Politano, A. et al. Tailoring the Surface Chemical Reactivity of Transition-Metal Dichalcogenide PtTe2 Crystals. Adv. Funct. Mater. 28, 1706504 (2018).

Song, S. et al. Electrically Robust Single-Crystalline WTe2 Nanobelts for Nanoscale Electrical Interconnects. Adv. Sci. 6, 1801370 (2019).

Lin, H. et al. Growth of environmentally stable transition metal selenide films. Nat. Mater. 18, 602–607 (2019).

Wang, D. et al. Passivating 1T′-MoTe2 multilayers at elevated temperatures by encapsulation. Nanoscale 9, 13910–13914 (2017).

Yu, Y. et al. High phase-purity 1T′-MoS2- and 1T′-MoSe2-layered crystals. Nat. Chem. 10, 638–643 (2018).

Lu, W. et al. Thin tungsten telluride layer preparation by thermal annealing. Nanotech 27, 414006 (2016).

Wang, Z. et al. Surface-Limited Superconducting Phase Transition on 1T-TaS2. ACS Nano 12, 12619–12628 (2018).

Hu, X. et al. Synthesis of NbSe2 single-crystalline nanosheet arrays for UV photodetectors. Cryst. Eng. Comm. 22, 5710–5715 (2020).

Yan, X.-J. et al. Investigation on the phase-transition-induced hysteresis in the thermal transport along the c-axis of MoTe2. npj Quantum Mater. 2, 31 (2017).

Hollander, M. J. et al. Electrically Driven Reversible Insulator–Metal Phase Transition in 1T-TaS2. Nano Lett. 15, 1861–1866 (2015).

Li, J. et al. General synthesis of two-dimensional van der Waals heterostructure arrays. Nature 579, 368–374 (2020).

Zhou, J. et al. A library of atomically thin metal chalcogenides. Nature 556, 355–359 (2018).

Schauble, K. et al. Uncovering the Effects of Metal Contacts on Monolayer MoS2. ACS Nano 14, 14798–14808 (2020).

Anemone, G., Al Taleb, A., Castellanos-Gomez, A. & Farías, D. Experimental determination of thermal expansion of natural MoS2. 2D Mater. 5, 035015 (2018).

Anemone, G. et al. Experimental determination of surface thermal expansion and electron–phonon coupling constant of 1T-PtTe2. 2D Mater. 7, 025007 (2020).

Wang, J. et al. High Mobility MoS2 Transistor with Low Schottky Barrier Contact by Using Atomic Thick h-BN as a Tunneling Layer. Adv. Mater. 28, 8302–8308 (2016).

Das, S., Chen, H.-Y., Penumatcha, A. V. & Appenzeller, J. High Performance Multilayer MoS2 Transistors with Scandium Contacts. Nano Lett. 13, 100–105 (2013).

Liu, W., Sarkar, D., Kang, J., Cao, W. & Banerjee, K. Impact of Contact on the Operation and Performance of Back-Gated Monolayer MoS2 Field-Effect-Transistors. ACS Nano 9, 7904–7912 (2015).

Kim, C. et al. Fermi Level Pinning at Electrical Metal Contacts of Monolayer Molybdenum Dichalcogenides. ACS Nano 11, 1588–1596 (2017).

Chee, S.-S. et al. Lowering the Schottky Barrier Height by Graphene/Ag Electrodes for High-Mobility MoS2 Field-Effect Transistors. Adv. Mater. 31, 1804422 (2019).

Yang, Z. et al. A Fermi-Level-Pinning-Free 1D Electrical Contact at the Intrinsic 2D MoS2–Metal Junction. Adv. Mater. 31, 1808231 (2019).

Cowley, A. M. & Sze, S. M. Surface States and Barrier Height of Metal‐Semiconductor Systems. J. Appl. Phys. 36, 3212–3220 (1965).

Yu, H., Gupta, S., Kutana, A. & Yakobson, B. I. Dimensionality-Reduced Fermi Level Pinning in Coplanar 2D Heterojunctions. J. Phys. Chem. Lett. 12, 4299–4305 (2021).

Ko, T.-J. et al. Wafer-scale 2D PtTe2 layers-enabled Kirigami heaters with superior mechanical stretchability and electro-thermal responsiveness. Appl. Mater. Today 20, 100718 (2020).

Chai, Y. et al. Making one-dimensional electrical contacts to molybdenum disulfide-based heterostructures through plasma etching. Phys. Status Solidi A 213, 1358–1364 (2016).

Hong, W., Shim, G. W., Yang, S. Y., Jung, D. Y. & Choi, S.-Y. Improved Electrical Contact Properties of MoS2-Graphene Lateral Heterostructure. Adv. Funct. Mater. 29, 1807550 (2019).

Suenaga, K. et al. Surface-Mediated Aligned Growth of Monolayer MoS2 and In-Plane Heterostructures with Graphene on Sapphire. ACS Nano 12, 10032–10044 (2018).

Chang, H.-Y., Zhu, W. & Akinwande, D. On the mobility and contact resistance evaluation for transistors based on MoS2 or two-dimensional semiconducting atomic crystals. Appl. Phys. Lett. 104, 113504 (2014).

Mirabelli, G. et al. Back-gated Nb-doped MoS2 junctionless field-effect-transistors. AIP Adv. 6, 025323 (2016).

Yang, L. et al. Chloride Molecular Doping Technique on 2D Materials: WS2 and MoS2. Nano Lett. 14, 6275–6280 (2014).

Liu, K. et al. A wafer-scale van der Waals dielectric made from an inorganic molecular crystal film. Nat. Electron. 4, 906–913 (2021).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Acknowledgements

This work was supported by the 2020 research Fund (1.200095.01) of UNIST, by Institute for Basic Science (IBS-R019-D1), and National Research Foundation (NRF) of Korea (Grant Nos. 2017M3A7B8065377, 2021R1A2C2094674, and 2021R1A3B1077184) funded by the Ministry of Science, ICT, and Future Planning. D.J and C.L. acknowledge support from Air Force Office of Scientific Research (AFOSR) grant FA9550-21-1-0035. This work has benefited from the use of the facilities at UNIST Central Research Facilities. J.-K.H. and S.K.M. partially used supercomputer Aleph supported by IBS Research Solution Center and high-performance computing resources of the UNIST Supercomputing Center.

Author information

Authors and Affiliations

Contributions

S.S. prepared materials and performed most of the experiments with assistance from J.Y., S.J., C.L., J.W., Y.S., D.J.; A.Y. and Z.L. conducted the (S)TEM characterizations; J.-K.H. and S.K.M. conducted the DFT calculations; S.S. and S.-Y.K. wrote the manuscript with the input of all other authors; all authors discussed the results and commented on the manuscript; S.-Y.K. supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Song, S., Yoon, A., Ha, JK. et al. Atomic transistors based on seamless lateral metal-semiconductor junctions with a sub-1-nm transfer length. Nat Commun 13, 4916 (2022). https://doi.org/10.1038/s41467-022-32582-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-32582-9

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.